Description

PopStop™ is a proprietary device (US Patent # 10,145,636 B2) that eliminates what is commonly known as first round pop (FRP) in suppressors. First round pop occurs when oxygen contained in a “cold” suppressor meets unburnt hot propellant. With certain suppressors, first round pop can account for more than twice the impulse noise as the subsequent shot through the same suppressor. PopStop interfaces between barrel and suppressor and utilizes a valve that allows for an injection of inert carbon dioxide into the suppressor via commonly available carbon dioxide cartridges and handheld tire inflators. The result is a suppressor purged of oxidation gas (oxygen) and replaced with an inert gas (carbon dioxide). We’ve tested the effects of PopStop lasting up to five minutes with a one second injection. The effects can last even longer if a condom (or similar) is used to seal the end of the suppressor post-injection.

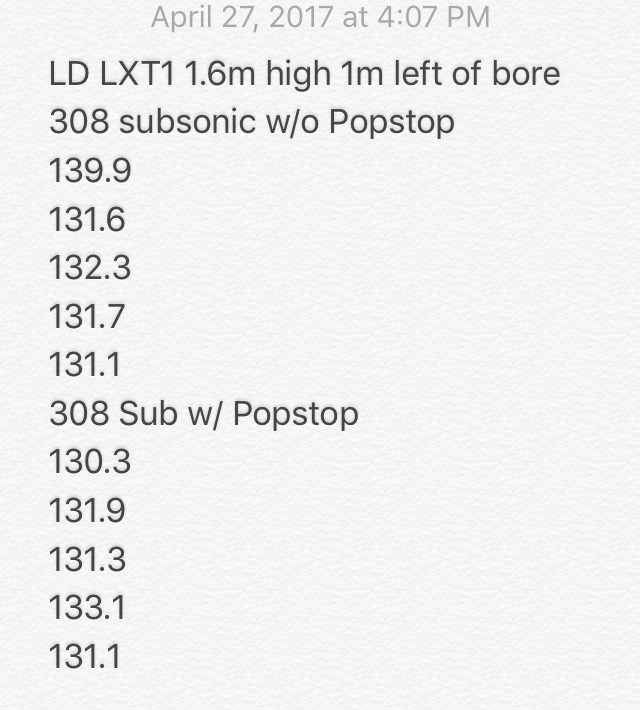

Using a calibrated Bruel and Kjar 2209 and Larson Davis LxT-1 sound impulse meters testing yielded a reduction of up to 9 dB by utilizing PopStop. Additionally, PopStop eliminates suppressor flash associated with FRP and can act to cool down the suppressor which helps reduce the POI (Point of Impact) shift commonly observed with certain suppressors. Finally, with one second injections before each shot, PopStop dramatically reduces velocity standard deviations.

PopStop is not intended for use with 9mm pistols as most 9mm threaded barrel shoulders are too short to properly function.

Barrel diameter of 1/2-28 threaded barrels must be a minimum of .590″ to properly time PopStop with the included shims.

A 1/2-28 spacer like the one found here may be required for some .22LR silencers to properly shoulder against the male end of PopStop.

For those with tapered 5/8-24 barrels a taper adapter like the one here may be required

Instructions:

1. Before attaching/threading PopStop™ SAFTEY CHECK the firearm to ensure it is unloaded.

2. Make sure threads on barrel are clean and clear of any debris.

3. Thread PopStop™ onto barrel. Assuming threads on barrel are cut to proper specification PopStop™ should thread on with little resistance.

4. Use included shim kit to position valve in preferred position. Recommend position is (looking down the firearm) pointed RIGHT for right handed shooters, and pointed LEFT for left handed shooters. If spacer is being used it should go against the muzzle shoulder.

5. Thread silencer onto male end of PopStop™. Torque to same spec as you would thread a silencer onto a barrel.

6. When ready to fire, chamber a round in the firearm and press CO2 inflator onto valve for 1/2 second. This will displace oxygen (noisy) in the suppressor and will fill the silencer with CO2 (quiet). Depending on internal volume of silencer the CO2 charge will remain in the silencer for up to 5 minutes – longer if condom (or similar) is used to cover muzzle of silencer

Co2 inflators like the one pictured below can be purchased on Amazon or Genuine Innovations

dB readings attained with a Larson Davis LxT-1 sound impulse meter using a bolt action 308WIN with subsonic rounds and YHM Phantom LT suppressor.

Prototype PopStop™ attached to an AR-10 during supersonic endurance testing.

Ruth –

Here is my page :: reduslim precio (reduslim.net)

AmandaUselo –

пп мешок

Carlosbic –

мешки для мусора 60

_kiki –

Недорого купить мешки для хранения строительного мусора

строительный мешок купить https://www.meshki-dlya-stroitelnogo-musora04.ru.

polietilen_evOn –

Упаковка из полиэтилена – это просто и эффективно

стрейч пленка 20 мкм http://orelpak.ru/catalog/streychplenka20mkm/.

Davidtrags –

Удаление катализатора Mercedes-Benz A-klasse AMG в Оренбурге

albuterol.bond –

ventolin.club : Inhaler Device and Inhalation Technique Selection in COPD Patients: A Critical Review albuterol inhaler side effects

JeffreyGom –

Власти Ливии выдают убитых повстанцев за погибших в результате авиаударов / Гейтс обвинил Каддафи в подтасовке жертв. Власти Ливии выдают убитых повстанцев за погибших в результате авиаударов коалиции, заявил министр обороны США Роберт Гейтс. По его словам, полученные разведданные свидетельствуют о том, что

viagrabrsm.com –

Stress, whether related to work, finances, or personal relationships, can significantly impact sexual function and contribute to erectile dysfunction.. http://viagrabrsm.com/ viagra cost walmart

CraigVek –

Hold on tight, because this news is going to blow your mind. better ties, easing border row Latest: China, India discuss better ties, easing border row I always suspected there was more to this story than meets the eye.

LucilleWhalk –

https://clck.ru/34acb5

RNS-MO-Sop –

Разрешение на строительство — это государственный письменное удостоверение, выдаваемый правомочными ведомствами государственного аппарата или субъектного руководства, который дает возможность начать стройку или выполнение строительного процесса.

Получение разрешения на строительство предписывает юридические положения и условия к строительным работам, включая предусмотренные типы работ, предусмотренные материалы и методы, а также включает строительные нормы и наборы защиты. Получение разрешения на стройку является обязательным документов для строительной сферы.

Vineri_iakt –

Наилучшие условия для покупки мешков для строительного мусора

мешки для строительного мусора от производителя мешки для строительного мусора купить.

Proizvodit_tjpn –

Классная полиэтиленовая продукция от нашего производителя

заказать упаковку в москве http://proizvoditel-polietilenovoj-produkcii.ru/.

Jamesnepay –

Я хочу поделиться своим опытом использования услуг частного специалиста по озонированию, которого я нашла по номеру 8 909 826 3556 (Комсомольск-на-Амуре), чтобы избавиться от трупного запаха в квартире, в которой я только что заселилась. После того, как я заселилась в свою новую квартиру, я обнаружила запах, который не могла установить и который становился все более неприятным с каждым днем.

В отчаянии я начала искать специалиста, который мог бы помочь мне с этой проблемой, и нашла контактный номер частного специалиста по озонированию. С первого звонка я поняла, что попала к профессионалу. Специалист был очень внимателен к моим проблемам и понимал, насколько это важно для меня.

Он согласился приехать и осмотреть квартиру, чтобы определить, что вызывает запах. Когда он прибыл, он проявил высокий уровень профессионализма и внимательно осмотрел все помещения. После осмотра он предложил провести озонирование для устранения запаха.

Процесс озонирования прошел без проблем, и результаты были поразительны. Запах исчез полностью, и воздух в квартире стал свежим и чистым. Я была приятно удивлена, насколько эффективно и быстро сработал этот специалист.

Кроме того, он был очень вежливым и профессиональным. Он ответил на все мои вопросы и дал мне рекомендации о том, как поддерживать чистоту в квартире в будущем.

В целом, я очень довольна результатом и рекомендую услуги этого частного специалиста по озонированию всем, кто столкнулся с подобной проблемой. Его профессионализм и качество работы заслуживают самой высокой оценки.

как избавиться от запаха гари на одежде

гарь запах после

нейтрализовать запах гари

запах гари после пожара

гарь запах после

как избавиться от запаха жареного в квартире

как избавиться от запаха после травли тараканов

запахло гарью